예, 하지만 이 맥락에서 "흑연"이 무엇을 의미하는지 이해하는 것이 중요합니다. 항공우주 엔지니어들이 흑연을 언급할 때, 그들은 연필에서 발견되는 부드럽고 부서지기 쉬운 재료를 거의 언급하지 않습니다. 대신, 그들은 현대 항공기 및 우주선의 필수 요소인 고급 복합 재료의 보강재 역할을 하는 고강도, 고강성 흑연 섬유를 말합니다.

핵심은 항공우주 분야의 "흑연"이 탄소 섬유의 동의어라는 것입니다. 이 재료는 폴리머 수지와 결합될 때 탁월한 강도 대 중량 비율을 제공하는 복합재를 형성하며, 이는 현대 고성능 항공우주 구조의 중추를 이룹니다.

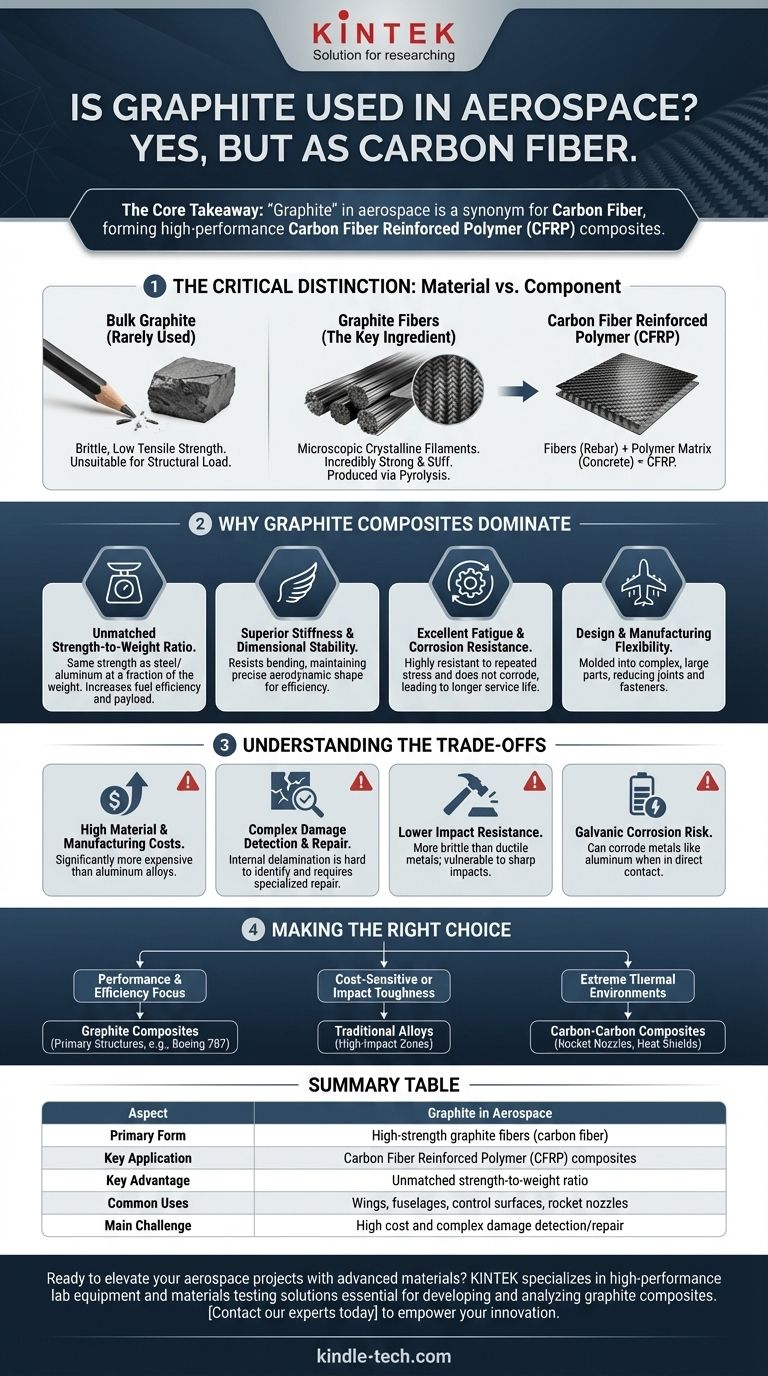

중요한 구분: 재료 대 구성 요소

그 역할을 이해하려면 원자재와 최종 엔지니어링된 부품을 구별해야 합니다. 이 둘은 근본적으로 다릅니다.

벌크 흑연은 거의 사용되지 않음

연필에 사용되거나 고체 윤활제로 사용되는 형태의 흑연은 항공우주 분야에서 구조적 응용이 매우 제한적입니다. 그 부서지기 쉬움과 낮은 인장 강도는 비행 하중을 지탱하는 데 적합하지 않습니다.

흑연 섬유가 핵심 재료

항공우주 분야에 혁명을 일으키는 "흑연"은 탄소의 미세한 결정질 필라멘트로 구성됩니다. 이 섬유들은 종종 인간의 머리카락보다 가늘지만, 길이를 따라 믿을 수 없을 정도로 강하고 단단합니다. 이들은 열분해이라는 고도로 제어된 가열 공정을 통해 생산됩니다.

탄소 섬유 강화 폴리머(CFRP)가 최종 제품

이 개별 흑연 섬유들은 직물로 짜이거나 시트로 정렬된 다음 폴리머 매트릭스, 일반적으로 에폭시 수지로 함침됩니다. 열과 압력 하에서 경화된 후, 이는 탄소 섬유 강화 폴리머(CFRP) 또는 더 간단하게 "흑연 복합재"라고 불리는 단단하고 견고한 재료를 형성합니다. 흑연 섬유를 철근으로, 폴리머 매트릭스를 모든 것을 함께 고정하는 콘크리트로 생각하십시오.

왜 흑연 복합재가 항공우주 설계를 지배하는가

알루미늄 및 티타늄과 같은 금속은 수십 년 동안 표준이었지만, CFRP의 고유한 특성은 많은 응용 분야에서 결정적인 이점을 제공합니다.

타의 추종을 불허하는 강도 대 중량 비율

이것이 가장 중요한 특성입니다. CFRP 구성 요소는 동일한 강도를 가지면서도 무게는 강철 또는 알루미늄 부품의 일부에 불과할 수 있습니다. 이는 연료 효율성 증가, 페이로드 용량 증가 및 성능 향상으로 직접 이어집니다.

우수한 강성과 치수 안정성

흑연 복합재는 매우 단단하여 하중 하에서 구부러짐과 처짐에 저항합니다. 이는 날개 및 제어 표면의 정확한 공기역학적 모양을 유지하는 데 중요하며, 최대 효율성과 예측 가능한 핸들링을 보장합니다.

뛰어난 피로 및 부식 저항성

반복적인 응력 주기(피로) 후 미세 균열이 발생하고 파손될 수 있는 금속과 달리, CFRP는 이에 매우 강합니다. 또한 알루미늄처럼 부식되지 않아 항공기 동체의 수명이 연장되고 유지 보수 비용이 크게 절감됩니다.

설계 및 제조 유연성

복합재는 금속으로 만들거나 만들기가 어렵거나 불가능한 복잡한 공기역학적 모양으로 성형될 수 있습니다. 이를 통해 전체 동체 섹션과 같은 단일 대형 부품을 생성할 수 있어 고장 지점이 되고 무게를 추가하는 연결부 및 패스너의 수가 줄어듭니다.

상충 관계 및 과제 이해

장점에도 불구하고 흑연 복합재는 완벽한 재료가 아닙니다. 엔지니어들은 상당한 과제에 대처해야 합니다.

높은 재료 및 제조 비용

원자재와 에너지 집약적인 제조 공정으로 인해 CFRP는 알루미늄 합금보다 훨씬 비쌉니다. 이 비용은 모든 설계 결정에서 주요 고려 사항입니다.

복잡한 손상 감지 및 수리

복합 구조물의 손상은 식별하기 어려울 수 있습니다. 금속 부품은 찌그러지지만, 복합재는 표면 손상이 거의 보이지 않으면서 내부 층간 분리(delamination)(층의 분리)를 겪을 수 있습니다. 이러한 구조물의 수리 또한 전문적이고 시간이 많이 소요되는 과정입니다.

낮은 충격 저항성

CFRP는 연성 금속보다 더 부서지기 쉬울 수 있습니다. 떨어뜨린 도구나 활주로 파편으로 인한 날카로운 충격은 재료의 강도를 저하시키는 상당한 표면하 손상을 일으킬 수 있는 반면, 알루미늄 스킨은 찌그러지기만 할 수 있습니다.

갈바닉 부식 위험

흑연 복합재가 특정 금속, 특히 알루미늄과 직접 접촉할 때, 전해질(수분 등)이 있는 환경에서 전기 회로를 생성할 수 있습니다. 이로 인해 금속이 빠르게 부식되는데, 이는 갈바닉 부식이라는 현상으로, 신중한 설계와 격리가 필요합니다.

목표에 맞는 올바른 선택

흑연 복합재 대 기존 금속 사용 결정은 특정 임무 요구 사항에 따른 복잡한 엔지니어링 상충 관계입니다.

- 최대 성능과 연료 효율성이 주요 초점인 경우: 흑연 복합재는 보잉 787 및 에어버스 A350에서 볼 수 있듯이 날개, 동체 및 제어 표면과 같은 주요 구조에 대해 우수한 선택입니다.

- 설계가 비용에 민감하거나 높은 충격 인성이 필요한 경우: 알루미늄 및 티타늄과 같은 기존 합금은 높은 충격 영역의 구성 요소나 비용이 주요 동인인 경우 여전히 필수적입니다.

- 극심한 열 환경을 위해 설계하는 경우: 탄소-탄소 복합재(섬유와 매트릭스가 모두 탄소인 경우)와 같은 특수 형태는 로켓 노즐 및 수천 도의 온도를 견뎌야 하는 차량 열 차폐와 같은 부품에 필요합니다.

흑연 기반 재료의 정확한 특성과 한계를 이해하는 것은 항공우주 공학 분야를 발전시키는 데 기본입니다.

요약표:

| 측면 | 항공우주 분야의 흑연 |

|---|---|

| 주요 형태 | 고강도 흑연 섬유(탄소 섬유) |

| 핵심 응용 | 탄소 섬유 강화 폴리머(CFRP) 복합재 |

| 주요 장점 | 타의 추종을 불허하는 강도 대 중량 비율 |

| 일반적인 용도 | 날개, 동체, 제어 표면, 로켓 노즐 |

| 주요 과제 | 높은 비용 및 복잡한 손상 감지/수리 |

첨단 재료로 항공우주 또는 실험실 프로젝트를 향상시킬 준비가 되셨습니까? KINTEK은 흑연 복합재 개발 및 분석에 필수적인 재료 테스트 솔루션을 포함하여 고성능 실험실 장비 및 소모품을 전문으로 합니다. 우리의 전문 지식은 항공우주 공학에 필요한 정확한 연구 및 품질 관리를 지원합니다. 오늘 저희 전문가에게 문의하여 KINTEK이 귀하의 혁신을 어떻게 지원할 수 있는지 알아보십시오.

시각적 가이드